What are Sapphire Windows?what are sapphire windows used for?

A window that uses sapphire as the material is known as a’sapphire window’. The name derives from the

fact that sapphire is one of the hardest natural substances and is perfect for high-pressure applications. It is also chemically inert to temperatures up to 1,000 degrees Fahrenheit and is highly scratch-resistant. Sapphire is second only to diamond in strength and durability. For these reasons, it is often chosen for its durability and longevity. Its transmission range from UV to mid-IR is comparable to that of quartz and fused silica.

What are Some Sapphire Applications?

Sapphire wafers can be used for any surface application. In addition to use in electronics, flat sapphire

substrates have been used for decades in optoelectronic applications, such as flat panel displays and microscopes. By placing one electrode in a substrate, scientists have been able to create a thin layer of metal oxide that absorbs all the ultraviolet light that hits the display or microscope, thus rendering it totally inaccessible to the human eye. Scientists are now using these flat substrates for photovoltaic applications, such as creating solar cells and solar concentrators.

A variety of scientific applications rely on flat sapphire, including chemical analysis, fluorescence, photoelectric effect measurement and crystal geling. This versatile material can be used for high-quality photographic plates and flat sheets as well. A common feature of sapphire is its ability to allow most color hues to pass through it, which is why sapphire engagement rings have always been a favorite of jewelers. Sapphires can be transparent or opaque, and often come in a rainbow of colors. While sapphire engagement rings cannot be manufactured in all colors, those that can be found are found in colors ranging from yellow-green through blue-white. These sapphires are also popularly used as rubies and emeralds, as well as being used to design watches and cufflinks.

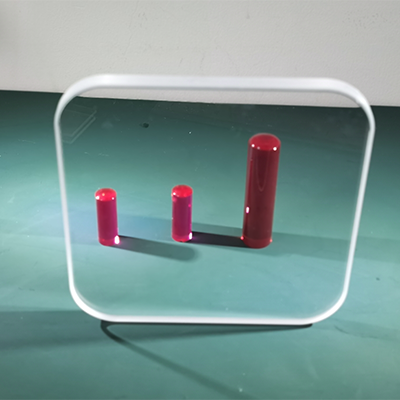

Sapphire Window Orientations

Most of us are familiar with the two major ways to develop a sapphire for optical applications. The first way is known as the “R-axis” and consists of flat plates, called waveplates, having flat troughs in their centers which are aligned to a particular rotation axis, usually referred to as the “Azimuthalignment”. This method produces a high quality image from a flat source. The R-axis is easy to apply, and requires little fabrication. The second method, named the “M-axis”, is more complicated and involves a much more precise alignment of the crystals.

Both methods of sapphire orientation are based on the same fundamental optical measurement called birefringence. Birefringence is a measure for the crystalline imbalance which occurs when a light wave strikes a light source. The best measurements for birefringence take place when the crystals are perfectly spherical, because near spherical crystals tend to have a higher birefringence than those which are slightly irregular. A high biref ration increases the sharpness of the image produced by a sapphire, improves brightness and also helps to produce better color rendition.

The second basic measurement, called the optical axis, determines the viewing angle for a sapphire crystal. This value is actually a logarithmically function of the primary azimuth, measured at different positions along the crystal’s axis of symmetry. It is usually denoted by a symbol representing the angle (or radii) on the horizontal and vertical axes. In the case of the R-axis, this angle is measured along the x-axis. In the case of the M-axis, it is measured along the y-axis.

The most significant influence on sapphire crystal orientation is found when the secondary, or top, surface of the crystal is flat. The flatness of the secondary improves the focal length and hence the resolution of the image or photograph. The sapphire and its orientation must be taken into consideration when a photographer is choosing a fast lens for his camera. The faster the lens, the sharper the image.

S Ascendancy is another important property of a sapphire. It indicates the orientation of the crystal on a plane that is coincident with the viewing frustum. In simple terms, when the viewing window is coincident with the sapphire’s plane of symmetry, the birefringence is balanced. When the window and the birefringence are not coincident, then the sapphire shows a positive birefringence.

Sapphire’s birefringence is proportional to the wavelessness of the water clear. This means that, for any given waveless level, the birefringe will be slightly less than one third of the distance between the plane’s axis of symmetry and the interior face of the crystal. It also means that the color and brightness of the natural sapphire are enhanced when light of a particular color is added to the detector. Another advantage of having a single crystal rather than two or more is that, for very low intensities, detectors equipped with infrared lights are far more effective than their conventional equivalents at resolving light.

The birefringence is made much thinner in modern sapphire windows than was the case in centuries past. The thickness of the birefringence is dependent upon the optical resolution required by the detector. Modern detectors have been designed so that they can resolve light at lower power than had been the norm in the past. In this way the quality of the final result is enhanced even though the optical system is made much thinner. A sapphire window with a single chip instead of two or more will provide much better optical resolution than a detector which has been made much thicker.

There are no special properties possessed by the sapphire crystal when it is viewed through an eyepiece. The refractive index of the crystal is exactly the same regardless of the direction in which it is viewed. In other words, no matter what the angle in which we view a sapphire crystal, it will always possess the same refractive index on account of the identical optical properties. The sapphire crystal only has an edge of zero, i.e. it does not refract light in the desired way.

- R-axis (10-12)

- C-axis (0001)

- A-axis (11-20)

- M-axis (11-10)